Atomic Energy Act No. 24 of 2008, empowers Council to conduct inspections to assess radiation safety and security conditions and compliance with the Act and the regulations and other requirements…

1.0 Introduction

Atomic Energy Council is government body established by the Atomic Energy Act No. 24 of 2008 with a mandate to regulate the peaceful applications of ionizing radiation for the protection and safety of society and environment from the dangers resulting from ionizing radiation. In Uganda ionizing radiation is used in the fields of medical, industrial, Agricultural, security, and Education & Research for various purposes.

2.0 What gives Atomic Energy Council powers to inspect

Section 9(1)(d) of the Atomic Energy Act No. 24 of 2008, empowers Council to conduct inspections to assess radiation safety and security conditions and compliance with the Act and the regulations and other requirements specified in an authorization.

3.0 What Atomic Energy Council inspects

3.1 Medical applications (for both diagnostic or treatment purposes)

- Diagnostic Radiology (e.g. plain X-ray Machines, Mammography machines, Dental X-ray machines, Computed Tomography machines among others);

- Interventional Radiology (e.g. Fluoroscopy Units, C-arm), Radiotherapy, Nuclear Medicine, among others.

3.2 Industrial Practices

Nuclear gauging (Level, Moisture, Density), Well logging, Industrial X-ray, Industrial Radiography, Industrial Computed Tomography, etc.

3.3 Security (for screening baggage or cargo)

Baggage Scanners, Cargo scanners

4.0 Reasons to why Atomic Energy Council carries out inspections

To ensure that:

(a) Facility design and layout, equipment and work performance meet all necessary requirements.

(b) Relevant documents and instructions are valid and are being followed.

(c) Persons employed by the operator (including contractors) possess the necessary competence for the effective performance of their functions.

(d) Deficiencies and deviations are identified and are corrected or justified without undue delay.

(e) The operator is managing safety and security in a proper manner.

(f) Any lessons learned are identified and propagated to other operators and suppliers.

(g) The authorized person is managing safety and security of sources in a proper manner.

5.0 Inspections conducted

AEC has inspected at least 90% of the registered facilities more than twice.

6.0 Types of inspections conducted by AEC

(a) Initial or pre-operational inspections (pre-authorization inspection) – carried out prior to a practice commencing work with radiation.

(b) Planned inspections (Routine) – Usually carried out at specified frequencies.

(c) Reactive inspections normally carried out with the purpose of making investigations when the regulatory body deems it necessary or as a result of an invitation from the facility.

(d) Final inspections; inspections carried out following cessation of the radiation practice or if an authorization is otherwise cancelled.

7.0 Frequency of inspections

The frequency depends on the risk associated with the practice. Practices are generally put into three categories by risk i.e. High risk, medium risk and low risk

(a) High risk practices such as teletherapy, irradiators, Computed Tomography, Fluoroscopy – Twice a year.

(b) Medium risk such as use of plain and dental X-ray machines, nuclear gauges – once in 2-3 years.

(c) Low risk such as bone densitometer, after 4-5 years and above.

8.0 Key issues considered during inspection in enhancing protection of the workers, patients, the public and the environment

8.1 Public Protection

Public protection is verified by checking;

(a) Shielding of the radiation premises

(b) Availability of security control measures both administrative and physical to rooms housing the radiation sources

(c) Availability of radiation warning systems such as notices, symbols and lights

(d) Location of the rooms storing the radiation sources

8.2 Worker protection

Worker protection is verified by checking;

(a) Availability of shielded cubicles

(b) Availability of work procedures and their implementation

(c) Availability of personal protective equipment

(d) Availability of radiation survey and monitoring devices

(e) Existence of communication channels within the facility

8.3 Patient protection (medical)

Patient protection (medical) is verified by checking;

(a) Performance of the medical equipment – performance parameters such as kV accuracy, Normalised dose output, Half Value Layer (HVL) among others,

(b) Availability and use of personal protective equipment,

(c) Medical request forms,

(d) Availability and implementation of Policy on pregnant patients,

(e) Availability of consent to treatment or diagnosis policy or forms

8.4 Environmental protection

Environmental protection is verified by checking the waste management measures/plans at the facility.

9.0 Impact of inspections

Increased compliance such as;

(a) Personal protective equipment now available in all facilities,

(b) Increased awareness on Council functions,

(c) Improved public awareness about dangers of ionizing radiation,

(d) Improved nuclear security of radiation sources in facilities,

(e) Increased number of monitored radiation workers,

(f) Improved public and environmental radiation safety and security,

(g) Improved management of disused radioactive sources.

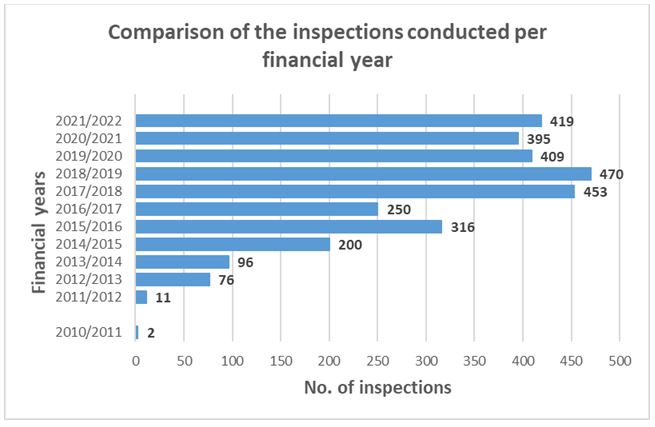

10.0 Trend of inspections conducted since 2010 – 2022

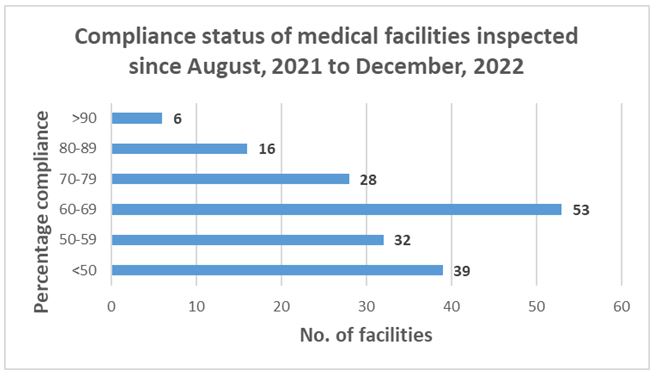

11.0 Compliance status of medical facilities inspected since August, 2021 to December, 2022

12.0 Challenges encountered during inspections

(a) Too much waiting time in some facilities.

(b) Unjustified exposure of inspectors at facilities which are inadequately shielded.

(c) Inadequate communication from facilities regarding change of location, addressing inspection requirements and recommendations, among others.

(d) Facilities not implementing quality assurance programs.

(e) Equipment without identification marks/specifications.

(f) Limited facility cooperation during inspections.